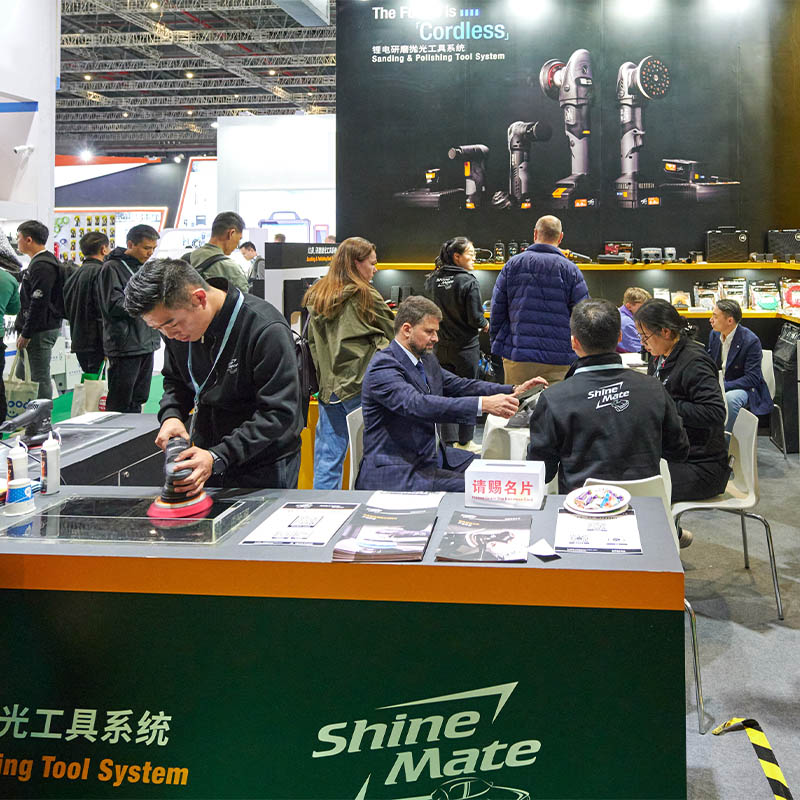

From body shop refinishing to car care detailing, ShineMate polishing tool system is built based on the deep integration and overall design of electric polishers, sanding and polishing accessories, and polishing chemicals.

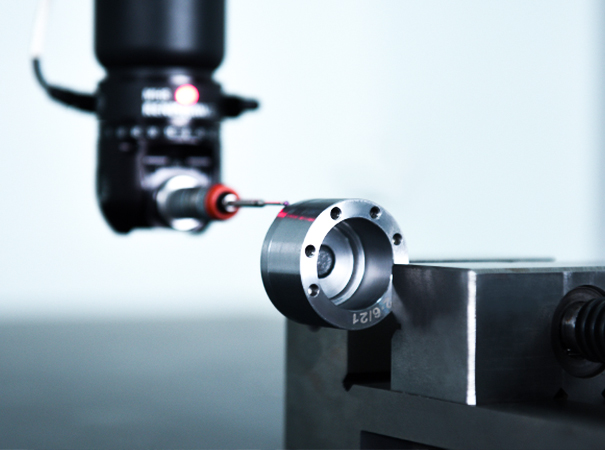

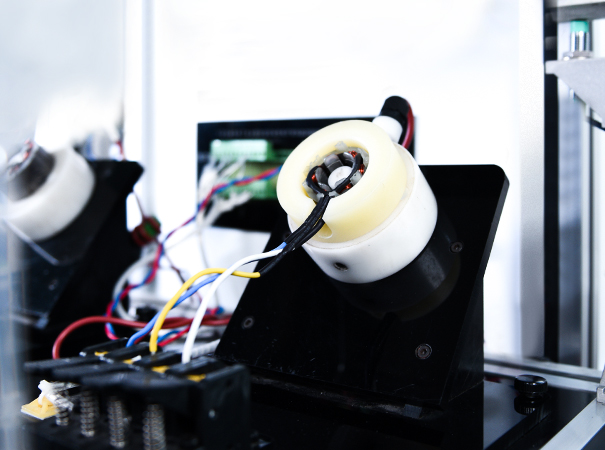

In order to reduce operator fatigue and achieve the perfect paint polishing effect, our electric polishers are not only lightweight, powerful, and comfortable to hold, but also have a leading eccentric balance control technology to suppress machine vibration.

ShineMate designed the Black DiamondTM diamond pattern foam pad, which covers the entire process from compounding to finishing, effectively reducing polish splash, giving stable control, and withstanding high-temperature and water wash, for swirl-free results.

……

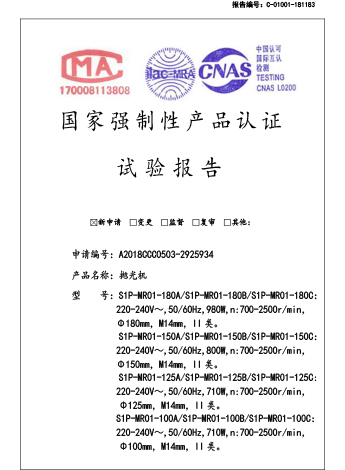

All these nearly perfect product combinations come from our in-depth research on the sanding and polishing process of paint surfaces, profound experience accumulation, innovation, and manufacturing capabilities of our own factories.

With excellent production process, affordable prices, and a good customer reputation, ShineMate has successfully won the trust and love of users and has become a famous automotive polishing tool brand sold in more than 80 countries and regions around the world.

Address: China operation center: Room 1305, Hangzhou Yin, No. 2030, Jianghui Road

Address: China operation center: Room 1305, Hangzhou Yin, No. 2030, Jianghui Road  Post code:310052

Post code:310052  Fax:+86-579-87208230

Fax:+86-579-87208230  E-mail:info@shinemate.com

E-mail:info@shinemate.com  WeChat:jothen

WeChat:jothen

Product Comparison

Product Comparison